In this article, we’ll look at what to consider when laser-marking metal components. The factors to consider include the line width, color, readability rate, and methods of marking. After we’ve covered these topics, we’ll move on to the actual process. Hopefully, this information will make your decision easier. if you’re looking to laser-mark a die cast part visit this website lasit.it

Line width

Choosing the appropriate laser for the marking job will greatly affect the quality and length of your mark. The type of laser will determine the line width as well as its power. This type of laser has leave a permanent mark that cannot removed by surface scratching or rough handling. The speed of the laser and its pulse frequency will also affect the line width. The higher the speed, the stronger the mark will, while the lower the speed, the weaker the mark will . The highest speed for laser marking will produce the deepest mark.

A laser used for laser marking should able to handle materials that are extremely dense, such as metal. The type of laser that you choose will depend on the material to marked. Fiber lasers have typically the most suitable for marking wood, but a CO2 laser can used to mark metals as well. It is important to note that no laser is universally applicable for marking on all materials. Listed below are some tips to help you select the appropriate laser for your marking needs.

Color

One of the key differences between laser marking and etched marking is the color. The former is a permanent marking, whereas the latter is not. Color laser marking requires a different method. An etching laser, for example, uses a laser beam to make a pattern on metal components. It can also mark plastic materials. However, these options are more limited than those for metal components. This article will discuss how the color of plastics can be marked using laser marking.

A laser marking system that produces a color pattern on metal components is generally used for traceability features and codes. These technologies are used in many fields, from the electrical and electronic industries to mechanical engineering, tool manufacturing, and medical technology. The process is also often used for promotional purposes. For example, Chinese can lid manufacturers use a FOBA laser marking system to apply QR-codes and characters to can lids. While it is not as common as a branded laser marking system, the process is still highly effective usglobalworld.

Readability rate

The readability rate of laser marking on metal components depends on many factors. In general, the higher the contrast between the marking and the surrounding surface, the better. Other factors that affect readability include the material, the type of marking, and the power of the laser. Using fiber lasers can significantly improve readability. They also have lower readability loss after heat treatment.

The automotive industry is committed to permanently marking safety-relevant components. These markings must be readable, durable, and resistant to abrasion, temperature, lubricants, and evaporation. To meet this challenge, laser marking is the ideal solution. As long as the laser is able to mark the parts, they can remain legible and durable, no matter what happens during production. With so many benefits, laser marking is a great choice for marking metal components.

Methods

Metals are a popular material for laser marking. There are many methods available, and they all work to create different types of markings. Some methods are more effective than others, however. For example, partial ablation produces a colored mark on a dark surface. Partial ablation works by removing a thin layer of the material, which can include paint or coating, dust, or rust. The laser energy then vaporises the material, revealing the surface below.

Before choosing a laser marking method, consider the type of material you are planning to mark. Different materials have different absorption spectra and react differently to various wavelengths. You will also need to consider the melting point and the response of the material to heat. For example, if your component is made of aluminum, it will be more easily damaged than a steel component. Additionally, aluminum has a lower melting point, which is another important factor when choosing a laser source.

Cost

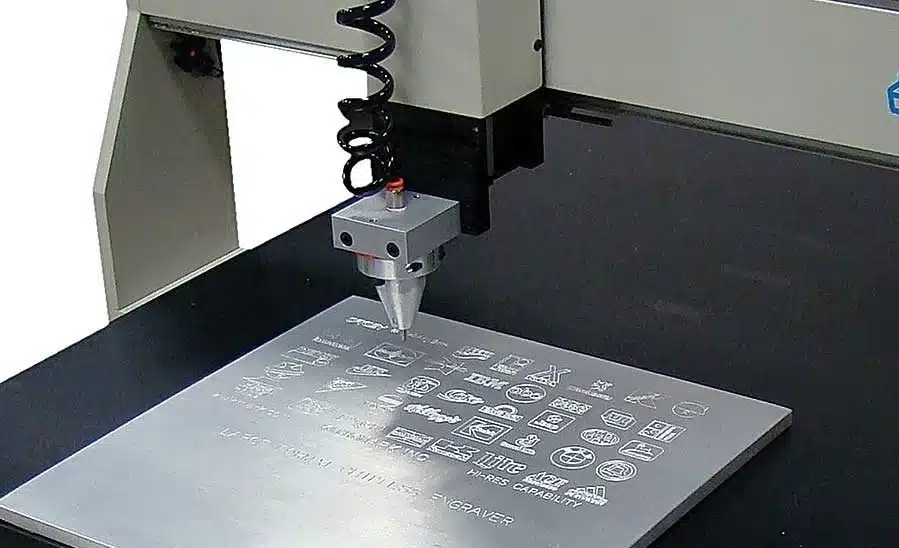

If you’re in the market for a new machine to make custom parts for your automotive company, laser marking is an excellent choice. Using a fiber laser can provide a number of benefits, including increased quality, energy savings, and cost savings. Additionally, fiber lasers can used to produce parts with greater detail, such as intricately patterned designs. This process involves removing some of the metal to create the engraved design.

Laser marking on metal components is an affordable process, with costs being as low as $0.02 per mark, which is far less than the price of ink or labels. Laser etching provides a permanent mark that can last for decades. Most industries find it advantageous, and it is an important component of meeting the requirements of the FAA and military. Moreover, laser marking minimizes the risk of product recalls and profit loss.

Getting More Information

PDF Drive: Everything You Need to Know In 2022

Best Smart Home Apps for Your Android Phone

Same day dry cleaning and laundry services

How to Find Absolute Care & Health

Luvmehair Review – Best-Kept Graduates’ Secrets

A Japanese Word That Means “Super 1 Awesome”

Learn Math from Online Math Classes